One of the main problems related to heat exchangers is the fouling. As already seen in other videos in our Tempco YouTube channel, when designing a heat exchanger the fouling factor must be considered, or anyway an over sizing of the thermal transfer surfaces in order to take account of the possible scaling of a heat exchanger.

Clearly it depends on the kind of fluids that flow inside it: having heat exchangers employed with clean fluids there are obviously no fouling issues and. Thus, it is possible to size the exchanger very precisely on the project working conditions, not considering too much the possible fouling effect and therefore a possible reduction of the thermal transfer surface.

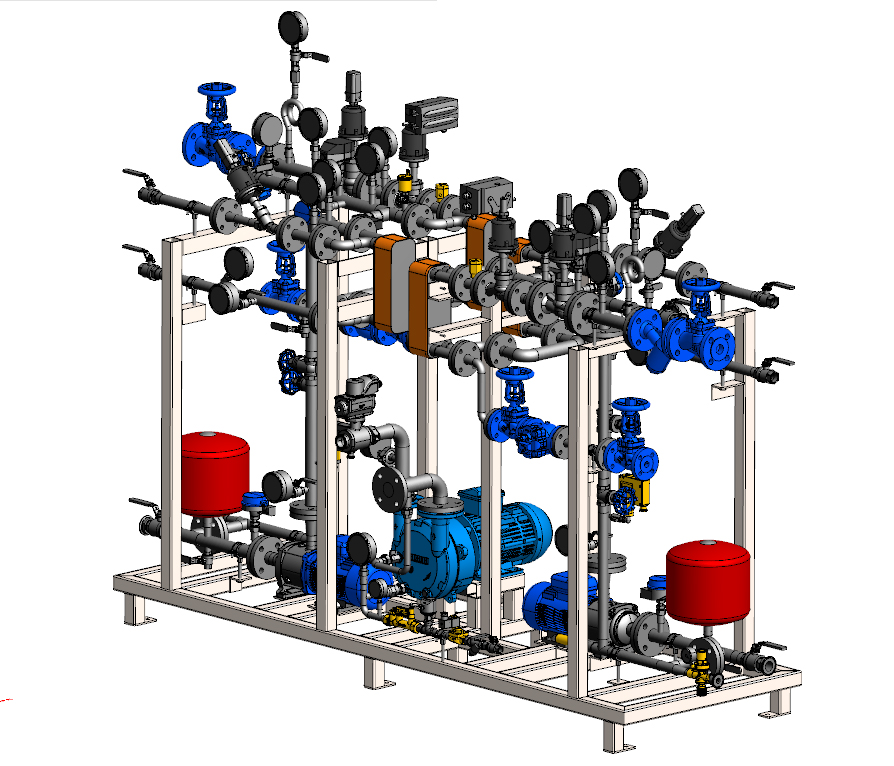

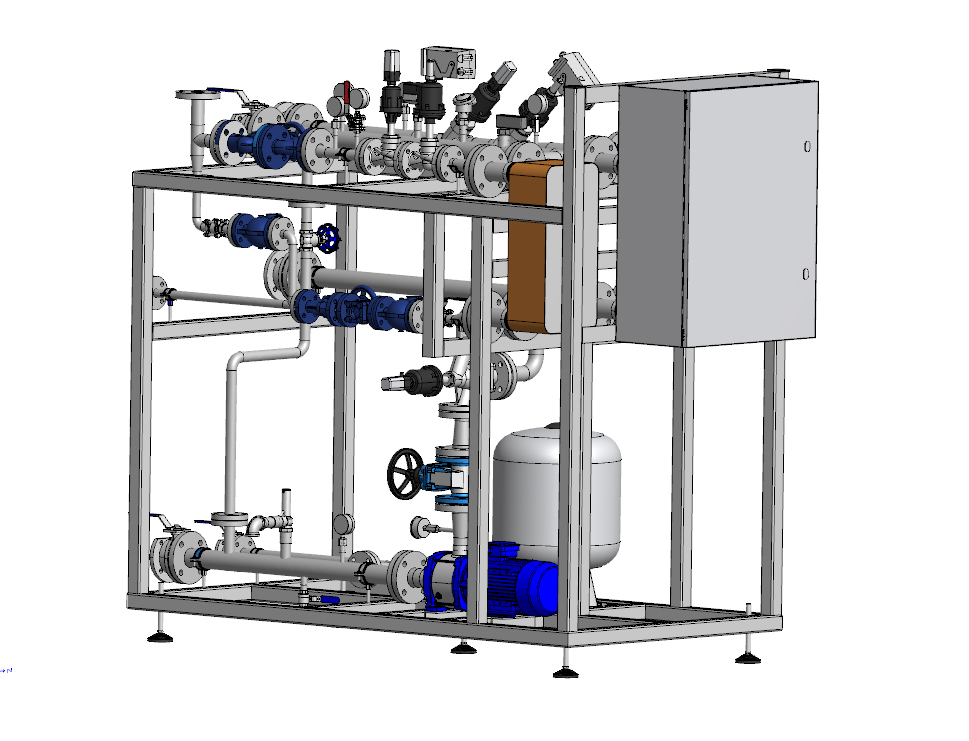

Instead, when fluids involved can be dirty then it is mandatory to carefully consider the fouling factor. The fouling level depends on the kind of fluids employed. There are several kinds of fouling: there is fouling involving a scaling effect, when there are fluids that get stuck onto thermal transfer surfaces. And this is probably the worst example. Otherwise, there can be fouling due to solid particles on the fluids circulating inside the exchanger. When fluids with suspended solid particles are involved there is a series of strategies to carry out in order to avoid fouling. On top of them there is filtration. Clearly, filters represent a bottleneck for thermal transfer because they reduce the flow rate of water, they involve pressure drops and thus requiring a higher pumping pressure, but they surely protect the exchanger from the fouling.

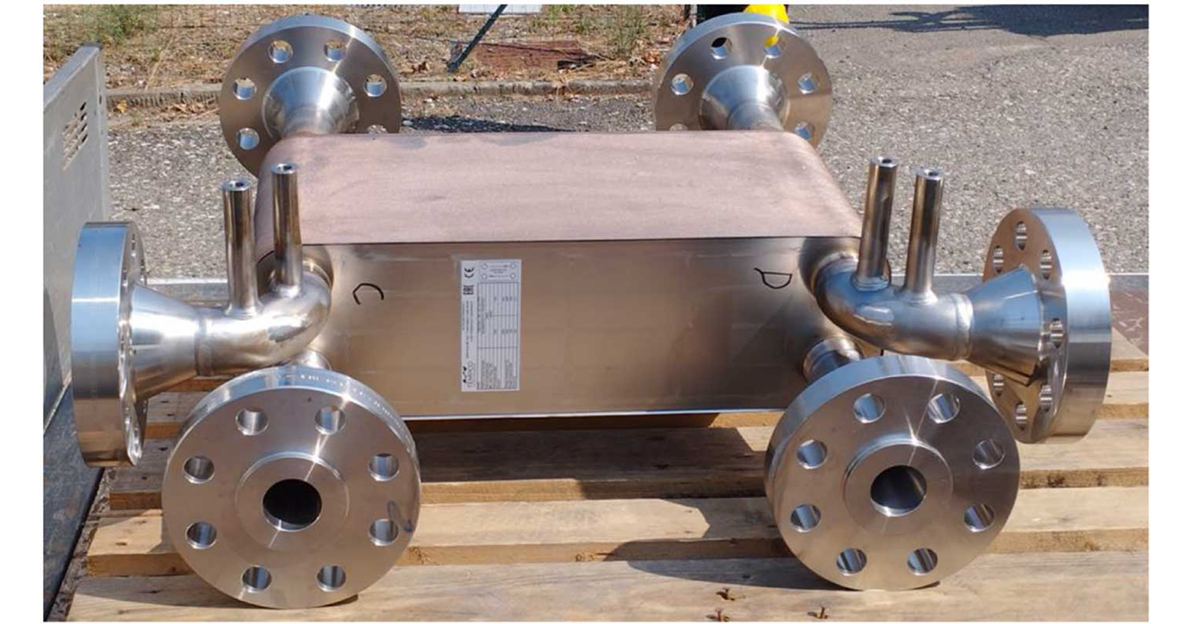

Obviously, there are even suspended solid particles that can be very small that are challenging even for a good filter. For example when using a kind of water with quite heavy suspended solid particles, such as sand, metallic swarf or fine dust. What is possible to do is to try to reduce the internal fouling of the exchanger, and we are speaking about plate heat exchangers, letting the fluid in from the bottom. In this way, the heavy particles tend to deposit on the bottom of the nozzle, and therefore not fouling all the plate, allowing to extend the maintenance periods.

Otherwise, fouling can be due to scaling, and let’s think about limestone, for example, or resins, as well about greasy products getting stuck on thermal transfer surfaces of plates. In this case, the only possible solution is a washing intervention that can be done in different ways: for example with a cleaning in place, or even dismantling the exchanger for a more accurate cleaning using a pressure washer, a brush or some washing cleansers.